On October 12, the NRRA staff and Facility Operators from New Hampshire, Vermont, and Massachusetts boarded a bus at 8:30am on the Fall Bus Tour. The plan for the day included a tour of the WIN Waste Wheelabrator Waste-to-Energy plant in Penacook, NH, followed by a tour of the newly-updated Gilford, NH Solid Waste Center.

In a follow up survey, it's clear the day was a win for all involved! Participants enjoyed getting an insider's look into how the WIN Waste facility worked: "It was very interesting to see the operations of the place and how we could really have a viable solution to our decreasing landfill space and higher power consumption."

Others commented on how helpful it was to see Gilford's new recycling center and hear about the process of bringing the idea of an upgrade to the town and working through the necessary steps to turn the idea into a reality. One participant commented, "I’m impressed with how Gilford adapted their solid waste and recycling needs...by building their own facility and changing from single stream recycling to source separation; all shows community support." Another participant noted that, "there are always worthwhile takeaways by visiting transfer stations and hearing their history, successes, and struggles."

It was also the first chance most participants - including NRRA staff - got to see the Foamcycle styrofoam recycling machine in action!

(Photos: Participants on the bus and ready to go!)

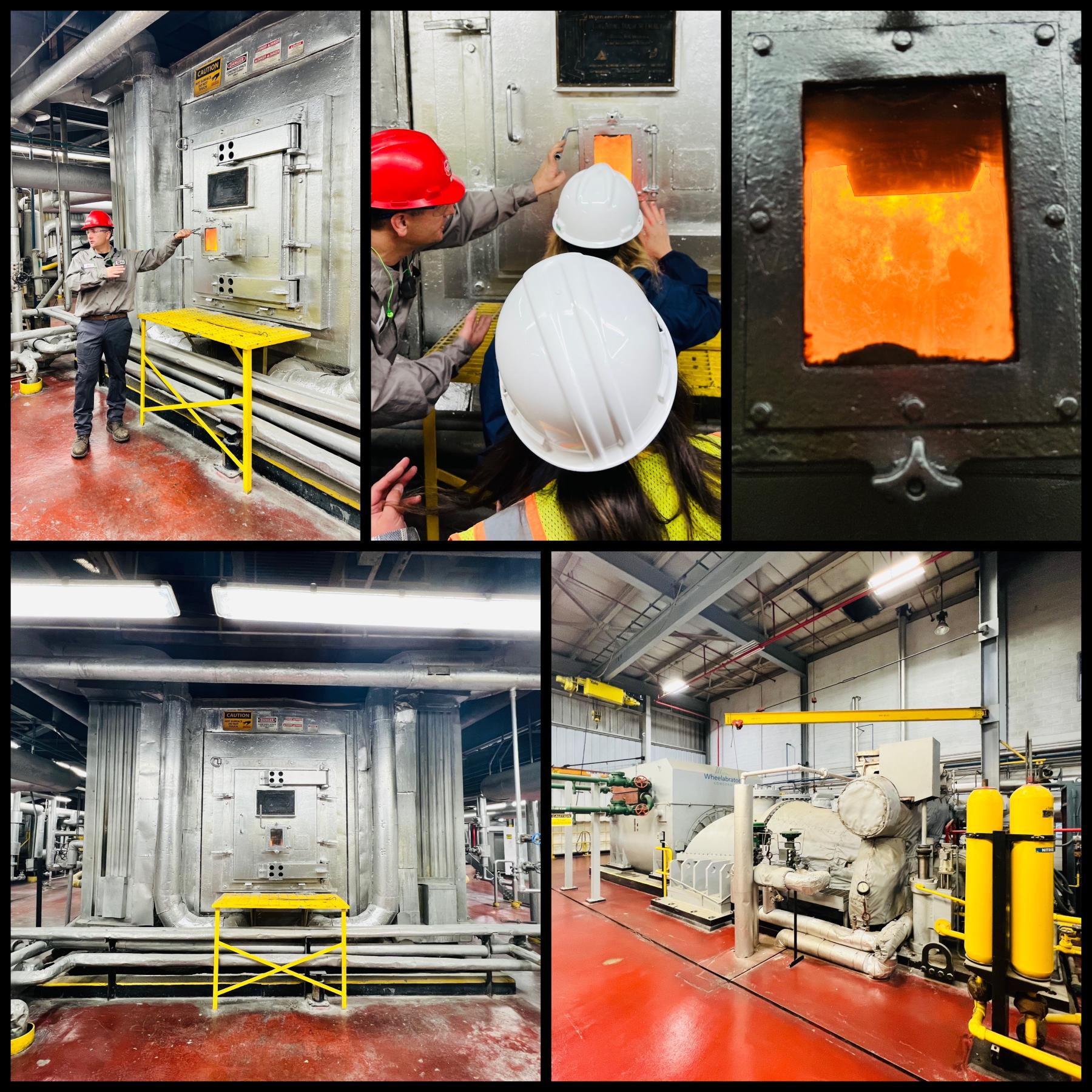

The WIN Waste Wheelabrator in Penacook was the first waste-to-energy plant in the US, opening in 1975. Participants were divided into three groups - one toured the facility, one received a presentation on how the facility operates, and one group got to enjoy some refreshments and time to network with fellow operators. Participants climbed several flights of stairs for a chance to look into the boiler where the trash is burned at temperatures up to 2500º Fahrenheit. From there, the group visited the turbine room where steam turns the turbines that create electricity.

(Photos clockwise from top left: Plant Manager, Matt Ayer, explains the boiler process; participants take a peek at the burning waste; burning waste; the turbines; the boiler)

Participants had the opportunity to visit the main operations room where computers monitor everything from temperature and speed of the boiler and turbines, to the weather and emissions from the stack. From there, participants were able to see the claw operator in action moving waste from the tipping floor to a pile, which is rotated based on imaging and the amount of time it's been on the floor. Waste is lifted from the pile into one of two hopper shoots that move the waste down into the boiler to be burned. A video of the giant claw in action was shared on social media.

(Photos clockwise from top left: Wheelabrator control room and two photos of the giant claw)

After the snacks, networking, tour, and presentation about the history of the WIN Waste Wheelabrator, Fall Bus Tour participants headed up to Gilford, NH with a short lunch stop on the way. Residents of Gilford recently approved the remodel of the Gilford Solid Waste Center. It was great for participants to be able to visit a newly-done recycling center and hear Gilford's Public Works Director, Meghan Theriault, talk about what worked (easy-to-access recycling bays) and what she would have done differently if she were to do it over again (a larger tipping floor).

(Photos clockwise from top left: the welcome and weight office as you drive into the Gilford Solid Waste Center; scooby treats for furry friends; a shot of the recycling bays.)

(Photos clockwise from top left: the welcome and weight office as you drive into the Gilford Solid Waste Center; scooby treats for furry friends; a shot of the recycling bays.)

(Photos clockwise from left: NRRA Executive Director, Reagan Bissonnette, and Gilford Director of Public Works, Meghan Theriault; NRRA Senior Member Services Representative, Bonnie Bethune, speaking with a participant; Reagan speaking with Sanbornton Transfer Station Manager, Shauna Goutier, and another participant)

(Photos across from top left: glass pile; participants looking out over back area; plastics and signage; glass hopper; horizontal baler; aluminum bales; mixed paper and signage; plastics bale; cardboard bales)

(Photos from left: walking out the back bay; two shots of the back area including happy participants and some beautiful fall foliage, along with neat recycling piles)

Participants also watched as three large bags of styrofoam was fed into the Foamcycle machine where it was chipped on the way in, heated so that the air could be pulled out and the plastic condensed down, and finally a slow, molten stream of compressed styrofoam is shaped into a fifty-pound ingot. Once Gilford has enough of these plastic ingots they will be sold and shipped off to be made into anything from foam insulation to frames. The Foamcycle machine is part of a pilot program Meghan is participating in to see about making styrofoam recycling easier and more accessible for facilities. A video of the FoamCycle machine in action was shared on social media.

(Photos clockwise from top left: the Foamcycle machine; feeding styrofoam into the running machine; the final foam ingot; Reagan verifying these blocks are HEAVY!)

(Photos clockwise from top left: the Foamcycle machine; feeding styrofoam into the running machine; the final foam ingot; Reagan verifying these blocks are HEAVY!)

THANK YOU to Meredith Transfer Station Supervisor, Michael Tarling, who took and shared many of the photos you see above!